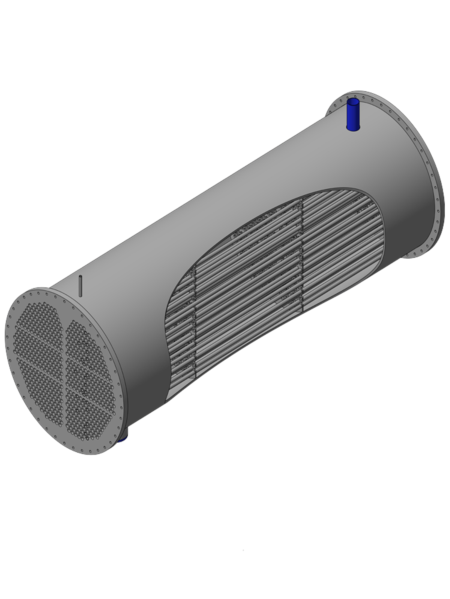

Industrial applications:

Chillers, MEE (multi-effect evaporators in ETP), Re-boilers, Oil coolers, heat pumps etc.

Capacities:

We can manufacture upto 56 inch Diameter and 20 ft length.

Our Unique features:

- Hinged dome or integrated davit arm for dome opening

- Wide range of tube metals and sizes

- Completely built in-house with inter stage inspections

- Color coded flanged ends as per requirements

- Very short delivery times